Manufacturers use specialized computer software or reference tables to determine the precise bend allowance determined by specific parameters.

Inconsistency of color match. If a fix is needed or a home extension is added a long time later on, it may be challenging to come across a precise match to the present metal.

The chamfer must prevent before the foundation of your element If you'd like to come up with a flange that has a couple of finishes chamfered, the past rule of the least flange duration still applies.

Generally, push brake bending is often a system technologies that modifies the plate or angle on the plate by exerting tension on it.

Mild metal sheet is a skinny, flat bit of steel with several apps. It could be obtained on the web and at any Metal Supermarkets spot, Minimize to your correct requirements.

The House between any holes and also the bend have to be at least two.5 occasions the sheet metal thickness. For slots, much more spacing is required. Slots need to be spaced at least four situations the sheet metal thickness from the sides of the bend.

This avoids later problems, overthinking and foolish faults. Dropping down below that benefit can convey problems your way. A larger radius will just make some other calculations a little harder.

The higher and reduce dies are mounted over the upper and lessen worktables in the press brake machine, respectively. The relative motion on the worktables is pushed by hydraulic transmission, and their shape, together Together with the higher and decreased dies, enables the bending formation of your plate.

Moreover, air bending minimizes the potential risk of harmful the sheet metal by avoiding immediate Call amongst the punch and also the die. Having said that, air bending needs careful calculation on the bend allowance to make sure precise Proportions and has restrictions about achievable bend angles.

Air bending is multipurpose, as metalworkers can utilize it to achieve a wide range of bending angles with just one set of resources. In addition, it minimizes tooling charges due to the fact only a single V-shaped die is necessary.

Max-Rib is really a minimal profile (3/4") panel which is very fashionable with homeowners across the nation resulting from its aesthetic enchantment and rate level. This panel profile is additionally very common while in the sector and several suppliers present this panel in numerous types of metal substrates and coatings.

Sequence 3xxx are the Aluminum – Manganese alloys. With the addition of 1% Manganese, these alloys have no considerable reduction in ductility, fantastic corrosion resistance, and Great formability. This collection is Probably the most preferable for forming

When compared to asphalt shingles, metal roofing stands up nicely to critical temperature like hail storms, weighty winds, and rainstorms. You’ll also help you save read on roof maintenance costs due to the fact metal roofs don’t want Regular repairs for destroyed shingles or tiles.

Sheet metal bending is usually a hugely successful system for manufacturing elements. Find out more about sheet metal bending nowadays!

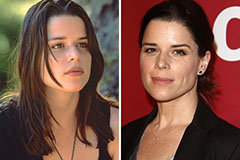

Neve Campbell Then & Now!

Neve Campbell Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now!